5-axis arbor – 五軸庵 –

木組みは美しくて大変スマートなジョイント方法であり、これを鋼管に応用した作品です。

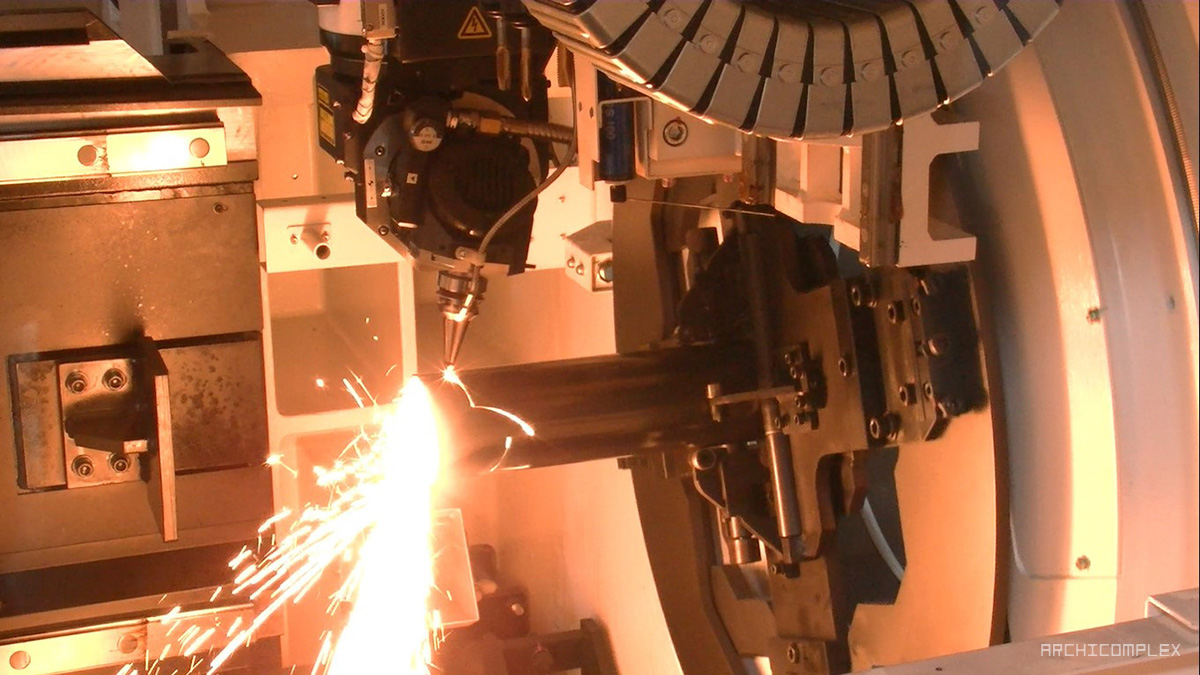

レーザー加工機は進化し、どのようなアングルからでも鋼管やH型鋼を切ることができます。無数の軸でレーザーヘッドを制御するので、通称5軸レーザーと呼んでいます。

小口を斜めにすることなども自在なのですが、問題はこのマシンに正確な命令を送れるほどの精度の高い3次元データを造れるかどうかです。

BIMは仮想空間でもあり、各部材は厚みや重量を持ちます。鋼管同士が斜めに交わる場合でも、どのような角度と曲線が相欠きを実現するかを正確に決定します。

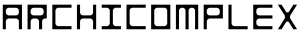

溶接やボルトを一切使わないで、ドーム状に鋼管同士を組み上げて安定させることに成功しています。

レーザー加工機は進化し、どのようなアングルからでも鋼管やH型鋼を切ることができます。無数の軸でレーザーヘッドを制御するので、通称5軸レーザーと呼んでいます。

小口を斜めにすることなども自在なのですが、問題はこのマシンに正確な命令を送れるほどの精度の高い3次元データを造れるかどうかです。

BIMは仮想空間でもあり、各部材は厚みや重量を持ちます。鋼管同士が斜めに交わる場合でも、どのような角度と曲線が相欠きを実現するかを正確に決定します。

溶接やボルトを一切使わないで、ドーム状に鋼管同士を組み上げて安定させることに成功しています。

There’s a construction method for making structures without any nails and glues in Japanese wooden architecture.

The nodes of the wooden structures have complex male and female joints.

Some joints can be made by skillful carpenters.

We were inspired by the traditional fabrication technique and have implemented the same technique using steel.

We have applied a multi-axis laser cutting machine, Mazak 400 Mk2, to cut steel pipes for building a new architectural space.

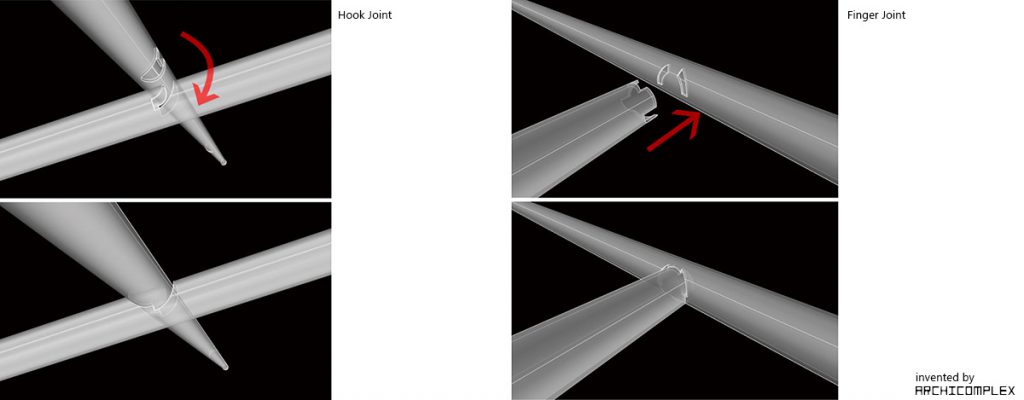

The laser machine can cut grooves on any curved pipe, and can shape skews on cut edges. So we can generate complex male and female joints for steel pipes.

The pipes connect to each other without any welds and bolts. We invented the Hook joint and Finger joint.

We have constructed a few 1 by 1 mock-up’s of steel arbor, Japanese tea ceremony houses. It is the most important phase to create a critical 3D file for cutting and simulating pipe connections in a sequential order. The machine contains many axes, however we have given the machine the name 5-axis laser for simplicity and to make it more easily remembered.

The nodes of the wooden structures have complex male and female joints.

Some joints can be made by skillful carpenters.

We were inspired by the traditional fabrication technique and have implemented the same technique using steel.

We have applied a multi-axis laser cutting machine, Mazak 400 Mk2, to cut steel pipes for building a new architectural space.

The laser machine can cut grooves on any curved pipe, and can shape skews on cut edges. So we can generate complex male and female joints for steel pipes.

The pipes connect to each other without any welds and bolts. We invented the Hook joint and Finger joint.

We have constructed a few 1 by 1 mock-up’s of steel arbor, Japanese tea ceremony houses. It is the most important phase to create a critical 3D file for cutting and simulating pipe connections in a sequential order. The machine contains many axes, however we have given the machine the name 5-axis laser for simplicity and to make it more easily remembered.